Managing a fleet of vehicles is no small task. Whether it’s a fleet of delivery vans, trucks, or service vehicles, keeping them running efficiently is critical to a company’s bottom line. When a vehicle is out of commission due to mechanical failure or improper maintenance, business operations suffer, and costs add up quickly.

Many fleet-related breakdowns and unexpected expenses can be avoided by recognizing and correcting common repair mistakes. Here are some of the most costly fleet repair mistakes that can lead to downtime, lost revenue, and unnecessary expenses for your business.

1. Skipping Preventative Maintenance

One of the biggest and most expensive mistakes fleet managers make is neglecting routine maintenance. Regular oil changes, fluid checks, tire rotations, and brake inspections help prevent major mechanical failures that can sideline a vehicle unexpectedly.

Waiting until something breaks down costs significantly more than keeping up with scheduled maintenance. Small issues like low oil levels or worn-out belts can escalate into complete engine failure or breakdowns on the road, leading to hefty towing and repair fees.

2. Ignoring Warning Signs

It’s easy to ignore a dashboard warning light if the vehicle still seems to be running fine. However, warning lights exist for a reason, and failing to address them can result in severe mechanical problems down the line.

Ignoring a check engine light could mean driving with a failing oxygen sensor, misfiring cylinders, or an overheating engine—all of which can lead to expensive repairs or even render the vehicle unusable. A quick diagnostic check can help identify and fix problems before they become major expenses.

3. Failing to Track Maintenance Schedules

Without proper maintenance records, it’s easy to lose track of when each fleet vehicle had its last oil change, brake inspection, or tire replacement. Failing to track these details leads to inconsistent maintenance, missed repairs, and higher long-term costs.

Having a fleet maintenance log allows businesses to:

- Schedule maintenance proactively instead of waiting for breakdowns.

- Identify recurring issues in certain vehicles.

- Reduce unexpected downtime and repair costs.

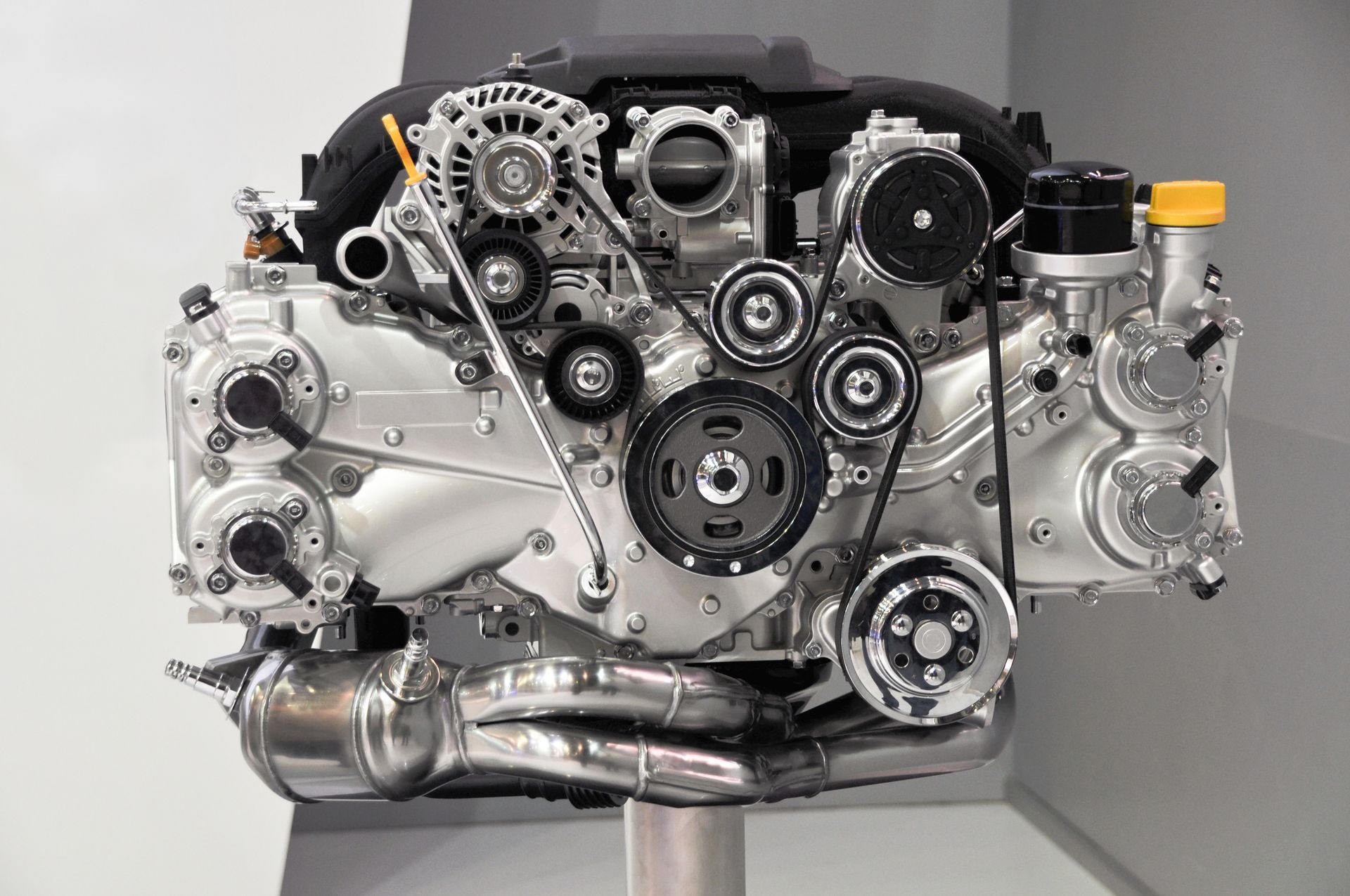

4. Using Cheap Parts and Low-Quality Repairs

Cutting costs by using cheap replacement parts or low-cost repair services often backfires. While budget-friendly repairs may seem like a good way to save money, low-quality parts wear out faster, leading to more frequent breakdowns.

For fleet vehicles that are driven daily, durability and reliability are critical. Investing in quality OEM or high-grade aftermarket parts ensures that repairs last longer, reducing downtime and minimizing future repair costs.

5. Not Rotating and Replacing Tires on Time

Fleet vehicles rack up mileage quickly, which means tires wear out faster than on personal vehicles. Failing to rotate tires on schedule or driving on worn-out tread increases the risk of blowouts, poor handling, and reduced fuel efficiency.

Proper tire maintenance includes:

- Checking tire pressure regularly to improve fuel efficiency.

- Rotating tires every 5,000–7,000 miles to extend their lifespan.

- Replacing worn tires before they reach unsafe tread levels to prevent roadside breakdowns.

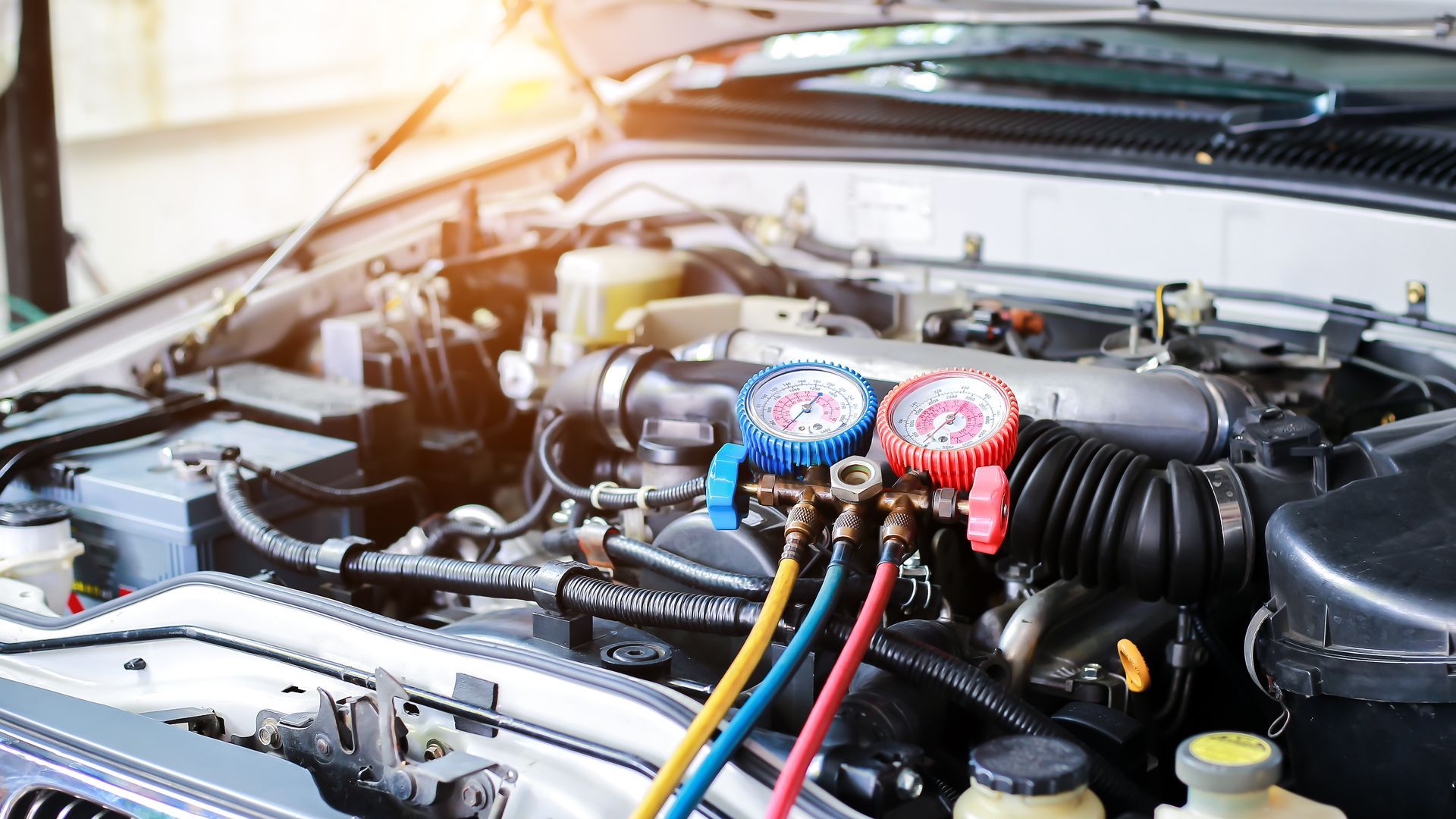

6. Overlooking Transmission and Cooling System Maintenance

Fleet vehicles experience more wear and tear than personal cars, especially when they are frequently hauling loads, driving in stop-and-go traffic, or operating for long hours. This makes transmission and cooling system maintenance essential.

Neglecting transmission fluid changes or coolant flushes can cause:

- Overheating, leading to blown head gaskets or engine failure.

- Transmission slipping or rough shifting, resulting in costly transmission rebuilds.

- Regular fluid inspections and flushes keep these systems in check and help prevent premature wear on critical components.

7. Delaying Repairs

It can be tempting to delay repairs on a fleet vehicle to avoid downtime. However, small issues rarely stay small, and pushing a vehicle beyond its limits can result in more costly breakdowns.

A minor oil leak, transmission slip, or brake squeak can quickly turn into:

- A seized engine that costs thousands to replace.

- A failed transmission that puts a vehicle out of service for weeks.

- Brake failure, which risks safety and increases liability.

Addressing minor repairs early is always cheaper and safer than waiting for a total failure.

Keep Your Fleet in Check with Brady’s Auto Repair and Diesel

Fleet repairs and maintenance don’t have to be a constant headache. By avoiding these common mistakes and staying proactive with maintenance, businesses can reduce downtime, extend the lifespan of their vehicles, and save thousands in repair costs. If your fleet needs reliable service, diagnostics, or preventative maintenance, expert help is just a call away.

Fleet breakdowns cost money—don’t let small issues turn into major expenses. Visit

Brady’s Auto Repair and Diesel for expert fleet maintenance.